To protect your employees, you must first consider collective solutions such as machine enclosure or sound insulation. If you can not intervene in the overall noise level, you must provide Individual Hearing Protective Devices (IHPD)

Click on the image or this link to display the computer graphics in full size

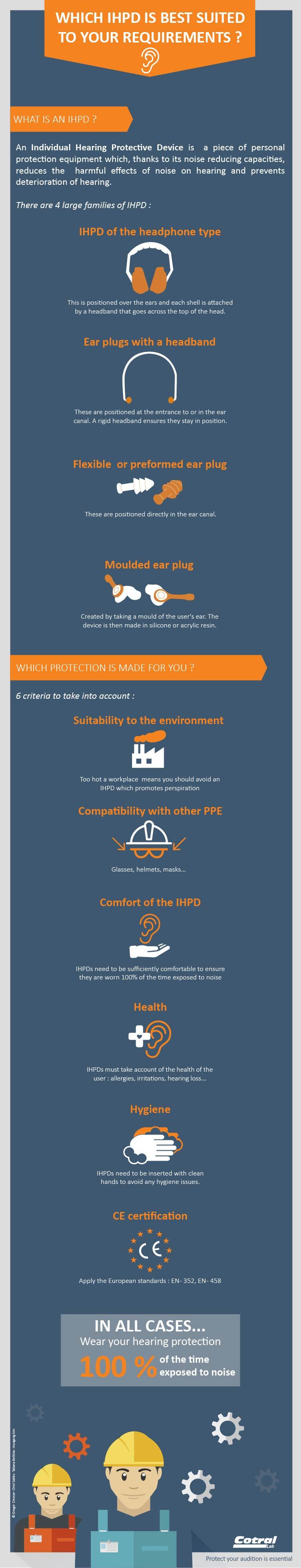

What is an IHPD?

An Individual Hearing Protective Device is a piece of personal protection equipment which, thanks to its noise reducing capacities, reduces the harmful effects of noise on hearing and prevents deterioration of hearing.

There are 4 large families of IHPD:

- Headphones: these are positioned over the ears and are attached by a headband across the top of the head

- Ear plugs with a headband: These are positioned at the entrance to or in the ear canal. A rigid headband ensures they stay in position.

- Flexible or preformed ear plug: These are inserted directly into the ear canal.

- Moulded ear plug or custom hearing protection: Created by taking a mould of the user's ear. The device is then made in silicone or acrylic resin.

The importance of protecting your hearing

The legislation defines two daily exposure thresholds, the use of IHPD is:

- Advised as from 80dB(A) in 8 hours

- Obligatory for the entire period of exposure to noise levels of 85dB(A) in 8 hours

The direct effects of noise on health are hearing loss, tinnitus and deafness. There are also indirect injuries such as cardiovascular disorders, vertigo, stress. Your company is at risk of a fall in productivity and an increase in work-related accidents due to reduced vigilance.

No matter which IHPD you choose, the important thing is to protect the hearing of your employees and that they wear their protectors 100% of the noise exposure time.

How to choose your hearing protection?

There are 8 criteria to take into account in your selection:

1. Adaptation of sound attenuation

It is not because a protector reduces more sound that makes it more effective. Your employee must be aware of his work environment: alarms, safety alerts from his colleagues. He must remain attentive to instructions and must therefore be able to communicate, exchange safely, that is to say without removing his hearing protection.

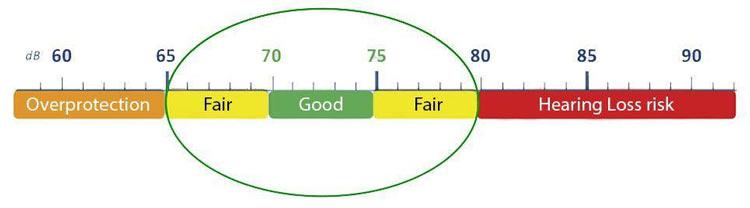

According to the EN 458 standard, an IHPD must lower the sound level perceived by the employee to 72 dB (A).

For example, Mrs. Rolland works in a 90dB (A) workshop, it is not advisable to provide her with an IHPD whose attenuation is 35dB. It is best to provide protection with an SNR between 15 and 20dB.

The choice of acoustic attenuation takes into account the equipment and the infrastructure but also the specificities of each one. Thus an employee who already has some hearing loss will not necessarily be offered the same reduction as his colleague who has no hearing loss even if they work on the same machine or in the same workshop.

2. Compatibility with other PPE

Double protection against noise

In some situations, wearing an IHPD is not enough to protect oneself completely from the risk of noise. When the intensity of the source is very high, it may be necessary to combine the wearing of two protectors, this is called double protection. Indeed, at some workstations, the ambient noise level can reach or even exceed 115 dB(A). In this case, the perceived loudness under the protection is very often higher than the admissible level. To combat such extreme exposures, custom hearing protection can be worn under a set of ear defenders.

Compatibility with other PPE: Glasses , helmets …

Other situations require the simultaneous use of two PPEs protecting different parts of the body. In noisy workshops with risks of dangerous products splashing, for example, hearing protection must be worn in addition to a pair of safety glasses. On construction sites, the employee must be able to wear his IHPD with a helmet.

If specific conditions exist in your workshops that require the use of more than one protective device, it is essential that there is compatibility between the PPEs.

3. Comfort

Your employees must forget that they are wearing hearing protection. They must adopt reflex use and not even think about spending a day without their earplugs. For this you need to provide them with the most comfortable protector possible so that it is worn 100% of the exposure time.

4. Hygiene

Whatever the type of IHPD, they are all in direct contact with the skin. Hygiene and maintenance of these hearing protectors is an essential factor to be considered . How do you clean them? How often? Will the employee be able to use them easily or will he have to wash his hands first? There are many questions that you must ask yourself and take into account when making your selection.

5. Health

Is your employee allergic to certain materials? Does he have skin irritation? Does he already have some hearing loss?

6. Ease of use

Wearing the IHPD that you supply should not be perceived as a bind for your employee. It must be easy to use and to put in place. The easier it is to use, the faster it will be accepted and used by your employee.

7. Adaptability to the working environment

You must also take account of the working environment in your selection of noise protection. The temperature of the workshop, level of humidity… for example in a workshop of 25C, the use of headphones will cause perspiration that will affect the comfort of your employee and may cause him not to wear his protectors 100% of his exposure time.

8. CE certification

Last but not least the IHPD must be CE certified in a accordance with EN-352-2. You need to check this and request proof of CE certification from your supplier.

Be vigilant in the case of custom hearing protectors. It is important to emphasize that it is the entire set that must be validated: the plug and the filter. So if a supplier manufactures the plugs but buys the filters from another provider, they must have new CE certificate for the whole. They should not only provide you with the CE certificates for the filters.

Find all these criteria and specific examples in the Guide below. Evaluate all the options available to you and take steps to combat workplace deafness in your company.