Employees working in food production companies are exposed to risks every day. One of them is occupational deafness. How to avoid it?

SUMMARY

- Hearing protection in the food industry

- Improving productivity in the food industry with Cotral Lab

- X-ray- and metal detector-visible hearing protectors

- Hearing protectors that are easy to replace or remanufacture

- Hearing loss due to noise at work: a growing problem

Hearing protection in the food industry

The issue of hearing protection in the food industry - and in processing industries in general - is a bit more complex than other industries.

Employers must protect the hearing of employees exposed to noise while respecting the purity of processed products.

When it comes to food processing, the highest standards of quality and hygiene must be maintained. Consumers’ lives, the reputation and future of the company or group are at stake at all times.

So everything must be done to ensure the trust, well-being and health of the consumer, as well as the employee.

The food industry is a high-pressure sector, so employees are also under real pressure to perform at their best. That’s why a large number of companies in this sector invest in the interests of their employees.

Improving productivity in the food industry with Cotral Lab

To begin with, you need to assess the noise levels and working conditions that each person faces.

A map of noisy areas and recorded noise levels can be produced, and if specific working conditions are also to be taken into account at certain workstations (temperature, humidity levels, etc.), it's important to address them.

Choosing the most suitable custom-made hearing protector

It’s essential to determine which will be the best hearing protectors and the best filtration for the employee using the SAPAN method (developed by HearingProTech).

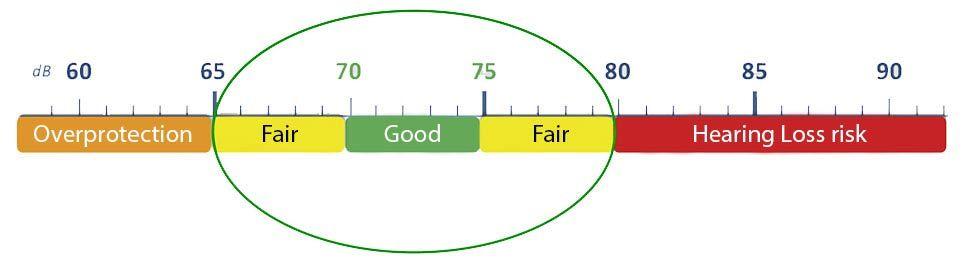

The aim is to place the employee’s level of perception at the best level so it isn’t overexposed to noise, but also so it isn’t underexposed, that is, between 70 and 75 dB.

Your employee will thus fall below the danger threshold for their hearing, but will be able to continue talking with their colleagues and, above all, hear any alert signal, audible warning, arrival of machinery (pallet truck, forklift) or problem on a machine.

The user must continue to be a player in their environment, and not become isolated in a bubble in which they would be at the mercy of a range of dangers.

Here at Cotral Lab, we also ensure that the protection continues to operate in freezing temperatures down to -20°C by choosing tougher materials for stronger cords that won't become brittle or break in the cold.

The attenuation efficiency of Cotral Lab hearing protectors

Their effectiveness is based on 5 commitments:

- CE certification,

- quality of ear impressions,

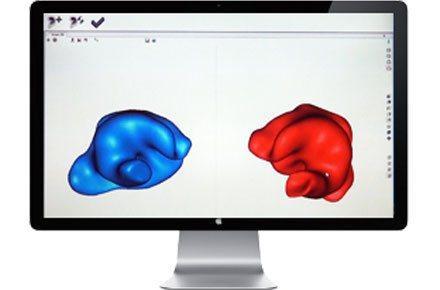

- 3D manufacturing,

- wide choice of attenuation (dB), ISO 9001 certification.

X-ray- and metal detector-visible hearing protectors

If you’re responsible for safety in a food processing company, the issue of safe hearing protection for people and production process shouldn’t be taken lightly.

There are three basic approaches to protecting food products from lost hearing protection:

- The first involves tackling the problem at source, i.e. preventing hearing protection from falling into the product, so it’s important that all the elements that make up a hearing protector are fully connected together and properly "attached" to their owner.

- The second is to make any part making up the hearing protection as visible as possible (handle, tip, cord, etc.), so the protection (and its accessories) must be a colour that cannot be found in food (for example, blue), allowing an employee to easily spot in the middle of the food a protector that’s accidentally fallen in at an earlier stage of the production chain.

- The third is to make it easily detectable if it falls in and no one can see it in among the food. Hearing protectors must therefore be X-ray-detectable or equipped with an electromagnetic element that prevents them from passing through the metal detectors built into the conveyors. These detection barriers must be placed at certain strategic locations to limit the distance travelled by an item which could have inadvertently ended up in a consumer product.

Copyright Photo Elex Industrie

Qeos custom hearing protection for the food industry

To help your employees meet rigorous quality and hygiene standards, Cotral Lab is constantly improving its range of custom-made hearing protectors designed for the food industry.

The protectors are made of Crylit, which is a quality material, hypoallergenic, washable and non-porous. So it doesn’t generate contaminants. This material is therefore particularly suitable for the food industry.

A hearing protector that’s fully detectable by X-rays and metal detectors

Food sector standards require being able to detect any possible foreign body using metal detectors as well as X-ray detection and inspection systems.

In accordance with these standards, Cotral Agro custom-made hearing protectors are designed to allow rapid detection in production line screening processes, and an electromagnetic patch is also present in the body of the hearing protector.

A handle and detectable cord can also be supplied with hearing protection in their Qeos Agro + version.

Hearing protectors that are easy to replace or remanufacture

One of your employees has misplaced one of their hearing protectors? No worries.

The digital file of the ear impression made by the Cotral Lab prevention technician (which was then scanned in 3 dimensions) is kept at our premises on our servers.

This helps reduce the remanufacturing time if necessary, as the files are stored during the warranty period, which is 6 years.

Comfortable hearing protection worn 100% of the time spent among noise

Cotral Lab custom-made hearing protectors are personalised (adapted to the user's sound environment and made to measure). They are not disposable, making them more cost-effective to use over 6 years than single-use products.

This is even more viable in the food industry, because it limits the risk of finding a disposable foam plug in food that’s inadvertently missed the bin…

By correctly protecting your employees' hearing with Qeos Agro or Clear Detect, you allow your teams to perform even better with comfortable hearing protection worn 100% of the time spent among noise.

Hearing loss due to noise at work: a growing problem

Despite growing awareness of hearing loss, the amount spent on cases of occupational deafness, and increased efforts to combat it, the incidence of noise-induced hearing loss among industry employees - food processing and others - continues to increase.

A recent survey on world health showed that hearing problems among people aged 45-64 have increased by 26% over the past 30 years.

This means that safety professionals must not only consider traditional noise reduction ratings (SNRs) to ensure good protection for employees' hearing, but also take into consideration the human factor that compromises hearing conservation efforts.

Above all, this highlights the need for employers to effectively protect employees' hearing by providing them with practical and effective personal noise protection equipment that will be worn continuously throughout the working day.

So like the groups Nestlé, Ferrero and many others... Trust Cotral Lab to protect the hearing of your employees in the food industry.